A California rocket-maker will start producing simple ventilators

The final devices are expected to cost between $200 and $500 each, compared to the $20,000 to $30,000 price of sophisticated ventilators. …

It’s not rocket science, but it could save your life.

Richard Branson-backed Virgin Orbit, with a factory nestled up to the airport in Long Beach, California, builds rockets to launch satellites from planes.

Now, with the coronavirus sweeping the globe, the company is stepping up to manufacture a simple ventilator on its own dime, driven by a windshield-wiper motor. Physicians at the University of California, Irvine (UCI) say it could provide a stop-gap solution.

“This one is going to basically be for all the patients who need a ventilator but do not need a top-line ventilator,” Dr. Govind Rajan, the director of clinical affairs at the UC Irvine Medical Center, says. “That will free up all these top-line ventilators for the sickest of the sick.”

A ventilator is a machine that effectively breathes for a patient; in this case, while their immune system fights off a viral infection for which medical science has few alternate treatments. The world’s supply of these machines is under heavy strain, especially as critical patients may spend weeks using the devices even as new cases arrive in hospitals.

Modern ventilators can get fairly complicated, incorporating sensors to monitor the patient and multiple settings to configure the machines to specific health needs. Ford and GM are re-tooling their production lines to manufacture machines like these, but it will take time: By the end of April, Ford says it will have produced 1,500 ventilators.

In contrast, New York City officials say their health system, the hardest hit in the US, will need 10 times as many—15,000 ventilators—by early April, when epidemiologists forecast the outbreak there to peak. As the virus continues to exact its toll, the demand for these machines is likely to keep rising.

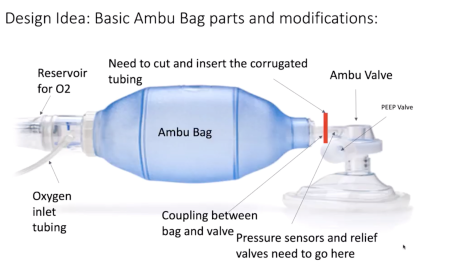

To help alleviate the pressure, a group of physicians and biomedical device experts hopes to start producing “bridge” ventilators in the coming weeks. These are simpler devices, akin to the handheld “ambu” bags used by paramedics to give oxygen to patients over brief periods of time, while in transit or before they have been intubated.

Rajan says the device was inspired by the start of his career in India decades ago, when doctors facing ventilator shortages would train family members to use handheld respirators to breathe for sick loved ones.

Just over a week ago, he and a team including Brian J.F. Wong, a UCI plastic surgeon who works in medical device development, and Thomas Milner, a University of Texas, Austin, biomedical engineer, kickstarted the the Bridge Ventilator Consortium. The ad hoc group is working to address the equipment shortages with an open source design that relies on parts that can be sourced at stores such as Home Depot or AutoZone.

Govind Rajan

The collaboration with Virgin Orbit began after CEO Dan Hart reached out to California state government with an offer to help, and was in turn connected to the consortium. Now, Virgin Orbit is confident it can produce the devices to offer a consistent, one-size-fits-all ventilation solution. The final devices are expected to cost between $200 and $500 each, compared to the $20,000 to $30,000 price of sophisticated ventilators.

“We’re not doctors and we’re not medical device manufacturers, what we do have is a lot of really smart engineers and a brand new, state-of-the-art factory,” Will Pomerantz, a Virgin Orbit vice president, told Quartz.

Like many aerospace companies, Virgin Orbit is considered an “essential business,” but the company has asked all employees who can telework to do so, and reconfigured its factory floor and procedures to allow employees to do their jobs in lower proximity.

Medical devices are typically produced in specially designed facilities to ensure safety and sterilization. Virgin Orbit is used to precision manufacturing and even has its own clean-room facilities for mounting satellites on their rockets, though they will need emergency regulatory waivers to allow their new devices to jump into the fray.

Today, Rajan was on a call with the White House ventilator task force, and says the ball is moving to get approval in Washington. Tonight, he is on-call at the Intensive Care Unit, where he expects to treat more patients with Covid-19.